Problems In ATX Computer Power Supply

Switch mode power supplies aren’t typically too hard to repair. They tend to fall into some categories:

1) Dead And Silent With Fuse Blown

Once you have opened up the casing and found that the fuse has blown, you have to expect some serious problem in the power supply unit. Of course there are also chances that the fuse has blown by itself due to life span of the fuse or from a mild surge. You may need to use the light bulb method as explained in chapter 13 to see if the problem is only the fuse or it could be some other components’ fault.

From experience, if you have discovered that the fuse blown, please check on these components like Varistor, Bridge rectifier, Big filter capacitor (swollen, leaked, open or short circuit), switching transistor, power IC and secondary output diodes (Schottky diodes) for short circuit. If you find shorted components anywhere in the primary side, you should also check the resistors for open circuit and replace as necessary. Do replace the bad components; fix any cracked solder joints, reassemble and then you are ready to test it. Use the light bulb method as explained in chapter 13 before you begin to put in the fuse and turn it On. Sometimes a severed power surge could cause the Varistor and the Thermistor to split open.

If you found that the primary side components burnt beyond recognition, (quite common if the SMPS was hit by lightning and had a major short circuit problem) you may need to refer to chapter 16 for further action.

2) Dead And Silent With Fuse Good

If the Main Fuse is Okay then I suggest that you check for an open start up resistor in the primary side (common problem) and also for a leaky switching transistor. Directly replace the power IC as we can’t accurately test the power IC with ohmmeter. A direct short circuit of the secondary output diodes could also cause no power symptom.

3) Power Chirping With Fuse Good

Chirping supplies (you could hear the sound of chirp-chirp-chirp) generally means there is a problem with the output. Shorted secondary

output diodes (Ultra fast or Schottky diodes) are the main cause of power supply chirping.

4) Power Cycling

By placing the test probe at the output connector, you will notice that the voltage reading goes up and down. The power supply is in a repeating cycle attempts to start up, but being dragged down by the overload and thus shut down and then the cycle repeats.

Since you could measure the output (although the output voltage is up and down) this suggests that the primary side switching transistor is working. If it is not working there would be no output at all. Thus your repair concentration should be in the secondary side. Check on the secondary output diodes and filter capacitors.

If the SMPS used power IC in the primary side, try checking the corresponding components like diode, current sense resistor or even the electrolytic capacitors before you replace the power IC and retest the power supply. If the SMPS used a Power IC, generally there would be a feedback circuit that uses the Optoisolator IC for regulation purposes. Check all the components in this area or even directly replace the Optoisolator IC and TL431 IC and retest the power supply.

SMPS Feedback Circuit

Note: Many computer SMPS require a minimum load to maintain stability and to provide proper regulation, thus when there is not enough load (under loaded), the power supply may be cycling due to overvoltage. Make sure that the load is enough otherwise you may be troubleshooting on a working SMPS and this would waste your precious repair time.

5) Fan Turns A Little Bit And Then Stops

The Fan Turns For A While And Then Stops

This suggests that the power supply is trying to start but because of faulty components in it, the power supply shuts itself off. In this case most probably the problem is in the secondary side. Bad ESR in secondary filter capacitor and capacitor bulged are very common in causing this kind of problem. These capacitors are specially designed to handle the rigors of filtering in a switch mode power supply and make sure that you test all these filter capacitors with an ESR meter.

Any capacitor that is swollen or leaking should be replaced. Faulty PWM IC (i.e.; TL494CN IC and etc) and corresponding components like resistor turned into high ohm could cause similar problem too. Don’t overlook that the regulation and the feedback circuit components which includes the Optoisolator IC (if the circuit has one) may also contribute to such problem. Check that the power supply is connected to a load (or original load) if not, the power supply fan would turn for a while and then stop.

6) High Pitched or Hissing Sound Problem-The power supply was working good (with good outputs) but it produced an annoying high pitched sound.

If the power supply is working good and you hear the high pitched sound then the problem could be in the SMPS transformer or from the secondary side inductor. If the transformer or inductor was not wound tightly and secured, they would vibrate. Try gently knocking on the transformer and the secondary side inductor with the handle of a screw driver while the power supply is running. If the sound goes away then I guess you have to remove either the transformer or the inductor (whichever one that produces the sound) and dip it into shellac and let it dry for a day. This method will usually get rid of the high pitched sound.

Components Replacement

If possible, get back the same part number to avoid repeating failures in SMPS that you have repaired and also to maintain the specifications within acceptable limits with respect to line isolation and to minimize fire hazards. However, if you still could not get the exact replacement part, then the only option you have is to get the nearest possible replacement part for substitution. Please refer to chapter 6 on how to get a replacement part number to insure reliable operation of the SMPS.

External Voltage Test Method

A TL494CN PWM IC In SMPS

If you come across any power supply that uses a PWM IC in the secondary side i.e. TL494CN then you can perform the following test to make sure it is good because if it doesn’t work, there will be no power. The PWM TL494 IC is the one that drive the switching transistors in the power supply. Although we don’t use oscilloscope in every SMPS repair, without it we may have some disadvantages especially in checking for the right signal or waveform. The problem with SMPS is that if the SMPS would not work, then how do we use the oscilloscope to test out the waveform? The solution is to use an external voltage source to power up the PWM TL494CN IC and check for the waveform.

First, check from the data sheet to see what is the DC voltage to power up the IC. Your ultimate aim is to supply the IC with the right voltage so that you could measure the waveform with your oscilloscope.

Now, connect a 12 volt dc supply to the input pin (pin 12) of the IC and the negative to pin 7 (ground pin) or to the secondary cold ground. If you do not have a DC power supply, you may use batteries to power up the IC- it works too! Once the 12 volt is applied to the IC, use your scope to check the output waveform at pin 8 and 11. You should expect an active square waves as seen in figure 19.17 in the next page. If there is no output, try ground pin 4 (dead time control pin) and check again the output. If there is still no output, do replace the IC and retest. Do not overlook that sometimes a shorted or bad components that correspond to the IC could cause no output. For example, a bad LM339 comparator IC or an open resistor in the corresponding circuit could cause no output from the PWM TL494CN IC.

A Typical Squarewave Waveform At Pin 8 and 11 Of PWM IC TL494CN

This method will eliminate problem to someone who is afraid of doing troubleshooting while the SMPS is “On”. They are afraid of dealing with the high voltage thus this method would suit them the most.

Note: You can’t use this method to test on all kinds of PWM IC because most of the PWM IC has a feedback pin. That means if by just applying only DC voltage to the PWM IC without any signal to the feedback pin, no waveform will be produced. You have to make your own test from the information that you get from the IC datasheet and see the result for yourself because there are too many PWM ICs in the market.

ATX Power Supply Repair and Troubleshooting

1) No power

CASE NO 1:

Most electronic repairer knows that whenever there was a complaint of no power by customer, the first thing he or she will do is to check the fuse first with an ohm meter or with a continuity test. In this case, the main fuse was found to be bad and I did not stop there. I continued to look for any burnt components, bulged capacitors, loose joints and etc. I have also tested on some of the major components like bridge rectifier, switching transistor, Varistor (A shorted Varistor tends to blow up the main fuse) and secondary output diodes.

Since all other components were tested good, I connected a 100 watt light bulb across the fuse holder solder pad points and On. The light blinks for a while and then went off. This was a good sign that there was no major short circuit in the SMPS (please refer to chapter 13) on light bulb test. I then removed the light bulb and put in a new fuse and power on. The SMPS came back to life indicating only fuse problem and no other serious fault in the circuit.

Note: This is my normal procedure of troubleshooting any type of SMPS whenever I come across a faulty fuse. A bad fuse is not necessary due to a heavy short circuit. As mentioned, a fuse could go open circuit because of its life span and possibly from a mild surge.

CASE NO 2:

The complaint was no power; it was because the fuse had an open circuit. As usual when found that the fuse was not working, I would test on the other major components. The result was the two switching transistors (MJE13007) had shorted and both were mounted on the heatsink (as shown in figure 20.1 in the next page). Further check reveals two fusible link resistors (2.2 Ohm) also had an open circuit.

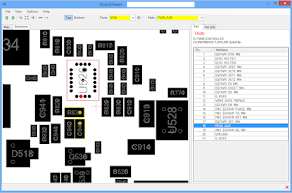

Power Transistors In ATX Power Supply

Please refer to case no 1 about connecting the light bulb before you switch “On” the power supply. Replacement of the 5 components (2 transistors, 2 resistors and 1 fuse) restored the problem.

Note: It is quite common when the fuse blown, the bridge rectifier or even the Thermistor and Varistor also will go shorted. Check the Varistor and Thermistor for cracks and pinholes. In some cases, the secondary output diodes might be destroyed too.

CASE NO 3:

The complaint was that there was no power but the fuse was working. Since the fuse was good, this shows that there were no major short circuits in the SMPS. Before performing any voltage test, I would usually check on the primary side components like the start up resistor, filter capacitor, non polarized capacitor and even direct replacement of the power IC and retest the SMPS. I will also scan for any short circuit in the secondary side output diodes too.

In this case, I found a non polarized capacitor in the primary side with the value of 0.47uf 250 volts dropped to 0.15uf when tested with digital capacitance meter. A replacement solved the no power symptom.

A Faulty Non Polarized Capacitor Can Cause No Power Symptom

Note: - Any components found defective in the primary side could cause a dead power supply symptom. Make sure you test on all the components in the power side and if all components were tested good, then directly replace the power IC (if the power supply used the Mosfet Technology) and retest the power supply. Some ATX power supplies may take you a longer time to troubleshoot because of ‘too many’ components in the board. The most frustrated part was that you could not get the spare parts especially the power IC. Even if you could locate one, the price would be sky high and if this happens, I will usually get the customer to buy a new unit since nowadays the price of a new power supply is quite cheap.

2) Intermittent No Power

This ATX power supply came in with the complaint of intermittent no power. When tested it with power on, I could see that the fan was not working. Not only that, some filter capacitors also became bulge because of the heat accumulated inside the power supply. The failure of the fan

could not suck out the heat generated by the components especially the switch mode power transformer, power transistors and output diodes. If you switched off a working power supply and with the ac power cord removed; and if you touch the power transformer, you could feel that the power transformer was actually quite hot. Another heat source would be the heat sink, where the power transistors and output diodes attached to it. Secondary output Diodes run a little bit hot in filter circuit than diodes in other circuits due to the high current present at the secondary output line.

The Right Way To Service The SMPS Fan

As for the malfunctioned fan, you could use a Philips oil based contact cleaner to service the fan. The grease inside the fan would run dry after serving for sometimes and eventually stop rotating. Remove the back plastic cap of the fan and spray it with the contact cleaner and you would be surprised that the fan could regain its glory. It will actually work just like a new fan. If it still doesn’t rotate, the best choice is to replace with a new fan. If you have the power supply at your work place then you could salvage the fan and install it.

Decayed Glue Found In ATX Power Supplies

From the photo above, you could see those decayed glue that stick besides the components. Manufacturers purposely use some kind of glue to apply on the components. They think those components will shake or come out when there is vibration or during shipping. The heat generated inside the equipment will turn the glue into conductive after a few years in service and sometimes would even corrode the pins of the components and eventually cause the equipment to have intermittent problem or totally stop working. Scrap the decayed glue off with your test pen and use a Thinner solution to clean the PCB board.

Bad Output Filter Capacitors Could Cause Intermittent No Power Problem

After the replacement of the filter capacitors at the secondary side, with the decayed glue removed and fan serviced, the ATX power supply again was given a new life to faithfully serve the computer.

3) Higher Than Normal Output

CASE NO 1:

When the power supply was switched on, measurements were taken. The results were over voltage. The 12 volts line shot up to 13 + volt and the 5 volts line became 5.6 volts. After the casing was removed, I noticed that the internal part was very dirty and I used a vacuum cleaner and a brush to clean off the dirt. Four filter electrolytic capacitors in the secondary side had bulged. The values of the filter capacitors were 1000uf 10 volt and 2200uf 10 volt

Dirt Inside The Power Supply

After Cleaning With A Vacumm Cleaner And A Brush

As you know, we as electronic repairers can’t just see things at only one side; we have to see the other side too. What I mean is that try to see if there are any more suspicious components that contribute to the failure of the power supply such as broken components, dry joints, loose connection, decayed glue and etc before the replacement of the four bulged filter capacitors.

Some components were covered with decayed glue. I had to carefully remove it by scrapping off the layers of the decayed glue. Once it was done, I cleaned the PCB board with the Thinner solution. As mentioned, decayed glue could cause serious or intermittent problem in electronic equipment because it could be conductive.

If you repair any ATX power supply, make sure you check the fan too. Please refer to page 248 on how you can service the fan.

The Four Faulty Filter Capacitors

Once the four electrolytic capacitors were replaced and the decayed glue removed, the power supply worked like a charm.

CASE NO 2:

If you found one of the output voltages were higher than normal, say from 5 V to 6 V or from 12 volt to 13 or 14 volt then checked for bad filter capacitors and surrounding circuitry. If all were tested good, do replace the Toroidal inductor as seen in figure 20.9 and retest the power supply. I have personally replaced quite a number of Toroidal inductors that had caused the output voltages to increase.

Replace the Toroidal Inductor If All Corresponding Components Were Tested Good

4) All output voltages were good but with some extra load (connected two additional hard disks) the power supply will shutdown.

This problem clearly indicates the secondary filter capacitors have problem because it can’t sustain additional load. True enough, when the casing was opened, I found out that a few of the electrolytic capacitors had bulged. For your information, if the capacitors are good, then you have to test it with ESR meter

Bulged Electrolytic Capacitors

Note: Do not overlook the fact that sometimes bad capacitors in the primary side (be it an non polarized or polarized capacitor) could cause the power supply to shutdown when extra load is connected.

5) High pitched sound from the transformer

This power supply was working well except that it produced an annoying high pitched sound. I suspected it was the transformer problem. Before I removed the transformer and dipped it into shellac as explained in page 242, I would usually scan some of the components first. I found two electrolytic capacitors with the value of 1 uf 50 volt had problem (bad ESR) in the primary side and the new parts solved the high pitched sound problem.

Note: Before dipping the transformer to the shellac, make sure no other components have problem especially the electrolytic capacitors (check the electrolytic capacitors with ESR meter) otherwise it still would not solve the problem because the problem is in the capacitors and not in the transformer. This will surely waste your precious time.

6) Power transformer has sound and the output voltages very low.

Here are the voltages measured at the output:

This power supply used the half bridge topology where a pair of power transistors (2SC3039) was used to switch the high voltage supplies across the primary winding of the SMPS transformer. Since there were some voltages at the secondary side, this suggests that the primary side was good. Because of this, my concentration was at the secondary side but I found nothing wrong with the secondary output diodes. I then moved on to test the small signal diodes (1N4148) at the input of the small transformer and found that both of the diodes had shorted. By replacing the two signal diodes made the SMPS work again.

Low Output Voltages Could Be Caused By Shorted Signal Diodes In The Secondary Side

Note: Not necessary the secondary output diodes shorted could cause sound in the transformer. It can also be some other shorted components like transistor, PWM IC, and capacitors. Do not overlook that resistors in the secondary side that have an open circuit or turn into high ohm could also cause similar symptom.

7) Output voltages were low and there was no sound from the transformer.

The output +5 volt became 2 volt; the 12 volt became 7 volt and power good signal was 0 volt. The fan could rotate (quite slowly but did not stop) and once the power supply was connected with extra load (hard disk) the fan stopped and power shut down.

This problem normally was the cause of bad secondary filter capacitors but somehow all the capacitors were tested okay. Since there were voltages at the output, this suggests that the switching transistors were good. It could also be some other component failure in the primary side that could affect the “on” time of the switching transistor thus producing a lower than normal output. Usually, capacitors in the primary side tend to have problems, so I checked on the non polarized capacitor first. Guess what? The non polarized capacitor .47uf 250v capacitance value became .19uf causing the SMPS to produce a lower output. Please refer to figure 20.2 to see where the non polarized capacitor is located.

8) No power good signal but all other voltages was good

Normally, when there is no power good signal (gray wire), we will trace back from the wire and check to see which location the signal was lost or to see if the signal source has any problem or not. But in this case, it seems that all the secondary side section was okay. I did not give up and try to check the primary side just in case if there is problem in the components. I knew the chances were quite slim because the SMPS has all the output (which means the primary side is working) except the power good signal only. I went ahead and test the big filter capacitor and surprisingly one of the big filter capacitors has problem. The value is 470uf 200 Volt and a replacement brought back the 5 volt power good signal.

One Of The Filter Capacitor Problem Could Cause No Power Good Signal

Note: Sometimes when you think that the problem lies in the secondary side it could also have some percentage of failure in the primary side. If you have exhausted finding fault in the secondary side, then try the primary side and vice versa. In the above case, I believed the ripples which were not removed by the big filter capacitor had entered into the secondary side causing problem to the power good signal.

9) Fan rotates a bit and then stopped and the transformer has sounds.

CASE NO 1:

As usual, whenever I come across this problem I will check on the secondary side filter capacitor with ESR meter and the secondary output diodes. Since the filter capacitors were tested good, I then proceed to check on the secondary output diodes. I will remove the big SMPS transformer and then check all the secondary diodes. The reason I removed the SMPS transformer was that I could test all of the secondary diodes (ultra fast recovery diode and Schottky diodes) on board without removing one of the diode leg. Secondly, sometimes I do come across decayed glue located underneath the transformer output pins and it will cause intermittent problem and you could hardly see the decayed glue from the top.

Checking all the diodes this way will give you a more accurate reading as compare when you check the diodes on board. Off course you can remove one lead in all the secondary diodes and test it with your meterit’s your preference. In this case, I found a diode shorted in the -12 volt output line (blue wire) and a new diode cured the problem.

A Shorted Diode In The Secondary Side Could Cause Fan To Turn A Bit And Stop

Note: Please do not think that every time when there is a complaint regarding the SMPS fan turning a bit and then stop, it must be the cause of a shorted secondary diode or bad filter capacitor. It could be due to other causes too- please read the next case to see what the solution to the problem is.

CASE NO 2:

First I thought it was one of the secondary output diode that was problematic but I found all of them were good. The secondary output filter capacitors were tested good too and the PWM TL494CN IC was replaced with no improvement. My concentration now was to check on the corresponding components of the PWM TL494CN IC. All components with one leg were lifted up and tested with meter and found two resistors had problem. A 47k Ohm that was connected to pin 14 of the PWM TL494CN IC changed to 70 over K Ohm and another resistor

.9 K Ohm that was connected to pin 1 of the IC had an open circuit. By replacing these two resistors brought the power supply back to life.

Faulty Corresponding Components Could Cause Fan To Rotate A Bit And Stop.

Note- It is not necessary whenever the fan rotates a bit and then stops, it must be the cause of shorted secondary output diodes. From the solution given above; it turned out to be the bad components that were located surrounding the PWM TL494CN IC. The PWM IC could turn out to be any part number and it depends on what model and type of power supply you are working on. A shorted PWM IC could also cause similar symptom too.

No comments:

Post a Comment